In the world of production, optimizing space in production plants and planning suitable layouts play a crucial role in the efficiency and performance of any manufacturing process. The organization of spaces and facilities can make the difference between a smooth and efficient production process and one filled with obstacles and logistical issues.

In this article, we will analyze the importance of these tools in manufacturing and production environments and how these practices can drive the success of companies in the food industry.

Why is space optimization so important in a production plant, and how does the layout influence it?

Plant layout design involves the arrangement of workers, production materials, machinery and tools, manufacturing lines, and workstations. The goal is to create a unique, functional, and efficient system. Among the various advantages of an optimized layout, the following stand out:

- Increased Safety Levels The top priority when optimizing the space of a production plant and developing an efficient layout is to design a safe environment that reduces the likelihood of accidents.

- Improved Operator Ergonomics Musculoskeletal disorders, mainly caused by poor posture and repetitive work in specific body areas, are the leading source of pain, discomfort, and disability worldwide. Therefore, an efficient design in the facility layout, being more ergonomic and comfortable, can contribute to the well-being of employees and a safer working environment.

- Increased Productivity All production processes face daily challenges, such as bottlenecks, where production slows down compared to adjacent operations. This can often be due to insufficient machine capacity, inadequate storage spaces, or low operator efficiency. A good design and optimization of spaces can resolve these issues.

- Minimization of Production Delays An optimal design eliminates space shortage issues and long distances for material movement, enhancing workflow and reducing production delays.

- Optimization of Available Spaces In a production plant, every square inch counts, and efficient design is the best way to make the most of the available space.

- Perfection in Quality Control To ensure proper product development, it is essential to conduct inspections at various production stages. Therefore, the facility design should facilitate inspections in multiple areas, contributing to more effective quality control.

- Ease in Supervision Processes A well-thought-out design is the first step towards achieving efficient space optimization in a production plant, thereby enabling effective supervision. It not only allows for an overall view of the environment and the location of each person but also makes it easier to be close to those who need support.

The Most Common Layout in Production Plants

In production plants, the product layout or line layout is predominantly used, where machinery and auxiliary services are organized so that raw materials are added or transformed continuously and sequentially as they move along the processing line.

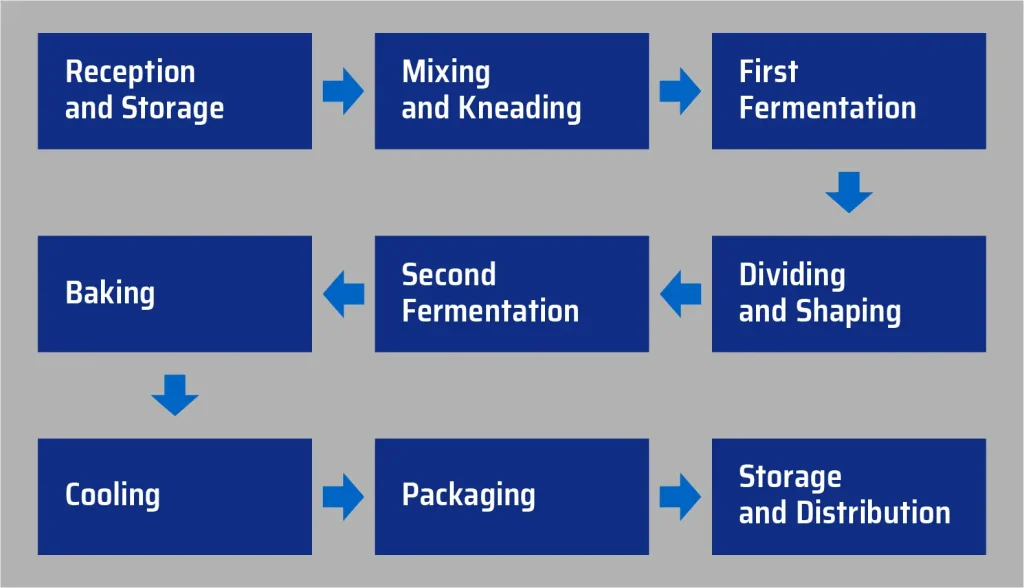

An example of this type of design can be seen in bakery production plants that use a line layout in their manufacturing process. In this process, raw materials are added in a specific sequence, with each workstation dedicated to a particular task, such as mixing and kneading, first fermentation, dividing and forming, second fermentation, baking, cooling, and packaging. The product moves from one station to the next in the production sequence, following the predefined order. This line layout ensures high efficiency and smooth flow in the bakery production process.

At Abreu, we work tirelessly to provide high-value-added equipment to the food industry throughout Latin America. We have a team of highly specialized professionals in engineering, design, project management, manufacturing, and technical support.

Through a range of products, including conveyor belts, shallow freezers, cold storage doors, and spirals (innovative products offering various applications such as lifting, descending, buffering, and product accumulation), we support a wide variety of clients in industries such as fishing, fruit and vegetable, refrigeration, poultry, dairy, and baking. Our solutions are designed to improve and optimize spaces in our clients’ production processes.